أرسل لنا رسالة

auxiliary drive ball mills

Industrial gear unit drive solution for ball mills SEW

Flexible drive solutions for use in ball mills A ball mill is a horizontal cylinder filled with steel balls or the like. This cylinder rotates around its axis and transmits the rotating effect to

Industrial gear unit drive solution for ball mills SEW

Ball mill. Ball mills are used to grind and mill various materials. Our drive solutions from perfectly compatible components (from the industrial gear unit through to the girth gear)

Energy efficient cement ball mill from

The mill drive is provided with an auxiliary drive for slow turning of the mill. The LGDX includes two independent lubrication systems, one which services the girth gear

MINING APPLICATION: INCHING DRIVE SYSTEM ON A

TAILOR MADE SOLUTION. Planetary gearbox of RR Plus series with specific features for inching drive system, which is used as an auxiliary system to the main drive for a large

sbm/sbm auxiliary drive ball mills.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

New Auxiliary Drive for Ball Mill ABS, Atlantic Bearing

202192 New Auxiliary Drive for Ball Mill atlantic-bearing Operational Background The main drive has a 2000 hp, 200 rpm synchronous motor coupled to a

Selecting Inching Drives for Mill and Kiln Applications

2016521 The inching drive, also known as a barring or auxiliary drive, is an important component of any mill or kiln installation. It is used for maintenance and

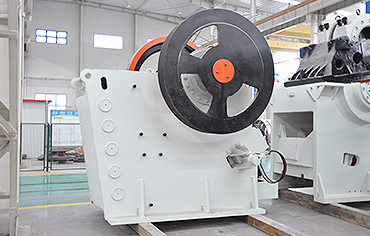

Ball Mill Ball Mill with Auxiliary Drive Manufacturer from

Manufacturer of Ball Mill Ball Mill with Auxiliary Drive, Ball Mill with Simple Drive, Ball Mill With V Flat Drive offered by Ghosh Metal Works Private Limited, Serampore, West Bengal.

Inching drives one way to improve mill safety Metso

2022411 The typical mechanical inching drive motor speed is around 1500 to 1800 RPM while the mill inching speed is in the order of 0.1 to 0.15 RPM. Thus, the gear

auxiliary drive Linguee

"auxiliary drive" 8。 Translate texts with the world's best machine translation technology, developed by the

Energy efficient cement ball mill from

The mill drive is provided with an auxiliary drive for slow turning of the mill. The LGDX includes two independent lubrication systems, one which services the girth gear

New Auxiliary Drive for Ball Mill ABS, Atlantic Bearing

202192 New Auxiliary Drive for Ball Mill atlantic-bearing Operational Background The main drive has a 2000 hp, 200 rpm synchronous motor coupled to a friction clutch with a pneumatic control, which allows the former to connect to the pinion of the final reduction. This system made it very difficult to achieve precise

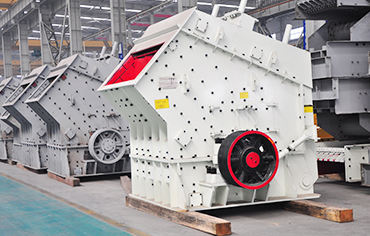

Ball Mills PSP Eng

201654 Mills are driven by a circumferential drive with a gearbox DMG 2 with two integrated pinions via a girth gear or with a gearbox, countershaft and one pinion for mills with a smaller diameter. An auxiliary drive is used for turning of the mill drum during maintenance. Mill shell Mill seating Mill drive Range of two-chamber mills

Selecting Inching Drives for Mill and Kiln Applications

2008522 The inching drive, also known as a barring or auxiliary drive, is an important component of any mill or kiln installation. It is used for maintenance and inspection purposes, as well as an emergency auxiliary drive to keep kilns rotating when the main motor fails. This stone covers what data the end user needs to provide for proper

Grinding Mills LR Sepro Mineral Systems Inc.

2019101 Sepro Tyre Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications, and are suitable for Ball, Rod and Pebble charges. Mills come complete with a variable frequency drive (VFD) package which allows you to fine tune the operation of the mill based on the charge and application. No auxiliary

SEPRO TYRE DRIVE GRINDING MILLS Sepro Mineral

20211122 Sepro Tyre Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications, and are suitable for Ball, Rod and Pebble charges. Mills come complete with a variable frequency drive (VFD) package which allows you to fine tune the operation of the mill based on the charge and application. No auxiliary

auxiliary drive Linguee

"auxiliary drive" 8。 Translate texts with the world's best machine translation technology, developed by the creators of Linguee.

What is an inching drive? Motion

201852 Image credit: Rexnord Corporation. An inching drive is used as an auxiliary system to the main drive for a large machine such as a ball mill, industrial kiln,

Autogenous mills, semi-autogenous mills and ball mills

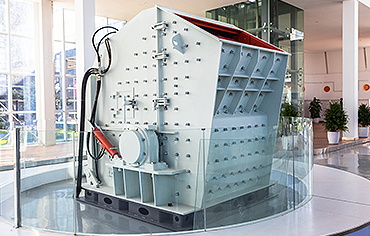

2017729 supported grinding mills up to the largest sizes. SAG/ball mill circuit incorporating pebble crushers and a POLYCOM® high-pressure grinding roll. SAG and ball mill for gold ore grinding. One of three SAG mills with 9.75 m diameter and 2 x 4000 kW drive power. These mills operate in conjunction with ball mills for iron ore grinding in Iran.

en/how brake operated in auxiliary drive of ball mill

. Contribute to sbmboy/en development by creating an account on GitHub.

MINING APPLICATION: INCHING DRIVE SYSTEM ON A

TAILOR MADE SOLUTION. Planetary gearbox of RR Plus series with specific features for inching drive system, which is used as an auxiliary system to the main drive for a large machine such as a ball mill. Its purpose is to turn the equipment at a speed slower than the normal operating speed — typically 1 to 2 rpm, although fractional rpms are

New Auxiliary Drive for Ball Mill ABS, Atlantic Bearing

202192 New Auxiliary Drive for Ball Mill atlantic-bearing Operational Background The main drive has a 2000 hp, 200 rpm synchronous motor coupled to a friction clutch with a pneumatic control, which allows the former to connect to the pinion of the final reduction. This system made it very difficult to achieve precise

Ball Mills PSP Eng

201654 Mills are driven by a circumferential drive with a gearbox DMG 2 with two integrated pinions via a girth gear or with a gearbox, countershaft and one pinion for mills with a smaller diameter. An auxiliary drive is used for turning of the mill drum during maintenance. Mill shell Mill seating Mill drive Range of two-chamber mills

Autogenous mills, semi-autogenous mills and ball mills

2017729 supported grinding mills up to the largest sizes. SAG/ball mill circuit incorporating pebble crushers and a POLYCOM® high-pressure grinding roll. SAG and ball mill for gold ore grinding. One of three SAG mills with 9.75 m diameter and 2 x 4000 kW drive power. These mills operate in conjunction with ball mills for iron ore grinding in Iran.

Ball Mill Ball Mill with Auxiliary Drive Manufacturer from

Manufacturer of Ball Mill Ball Mill with Auxiliary Drive, Ball Mill with Simple Drive, Ball Mill With V Flat Drive offered by Ghosh Metal Works Private Limited, Serampore, West Bengal.

SEPRO TYRE DRIVE GRINDING MILLS Sepro Mineral

20211122 Sepro Tyre Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications, and are suitable for Ball, Rod and Pebble charges. Mills come complete with a variable frequency drive (VFD) package which allows you to fine tune the operation of the mill based on the charge and application. No auxiliary

en/how brake operated in auxiliary drive of ball mill

. Contribute to sbmboy/en development by creating an account on GitHub.

Selecting Inching Drives for Mill and Kiln Applications

2008522 The inching drive, also known as a barring or auxiliary drive, is an important component of any mill or kiln installation. It is used for maintenance and inspection purposes, as well as an emergency auxiliary drive to keep kilns rotating when the main motor fails. This stone covers what data the end user needs to provide for proper

Industrial gear unit drive solution for ball mills SEW

Ball mill. Ball mills are used to grind and mill various materials. Our drive solutions from perfectly compatible components (from the industrial gear unit through to the girth gear) provide the necessary power. Flexible drive solutions for use in ball mills. A ball mill is a horizontal cylinder filled with steel balls or the like.

Ball Mill an overview ScienceDirect Topics

Conical Ball Mills differ in mill body construction, which is composed of two cones and a short cylindrical part located between them (Fig. 2.12).Such a ball mill body is expedient because efficiency is appreciably increased. Peripheral velocity along the conical drum scales down in the direction from the cylindrical part to the discharge outlet; the helix