أرسل لنا رسالة

grinding process in copper refining

Copper Smelting and Refining Process

In the furnace, the concentrates are instantly oxidized, after which they melt and separate by their own reaction heat into copper matte with a grade of 65% and slag consisting of

Copper processing Roasting,

This oxidation-reduction process is usually carried out in a separate furnace to ensure that the final smelter product reaches the level of 99.5 percent copper that is required

Processing of Complex Materials in

202076 Copper smelter and refinery with a copper cathode production capacity of 70,000 tpa. A precious

Copper Mining and Processing: Processing Copper Ores

A. Processing of Oxide OreB. Processing of Sulfide OreC. Recycling Copper

Oxide ores are generally processed using hydrometallurgy. This process uses aqueous (water-based) solutions to extract and purify copper from copper oxide ores at ordinary temperatures, usually in three steps: heap leaching, solvent extraction, and electrowinning. Heap Leachingis the process of using percolating chemical solutions to leach out meta...

Copper Refining an overview ScienceDirect Topics

Application Areas Miscellaneous Process Industries. David Reay, Adam Harvey, in Process Intensification (Second Edition), 2013. 10.5.1.5 Copper extraction using

17.5: Refining of Copper Chemistry

2022720 1. Figure 17.5. 1: The electrolytic purification of copper. In such a cell a thin sheet of high-purity Cu serves as the cathode, and the anode is the impure

Copper Refining: Explained Step-by-Step

2017210 In refining copper, the metal is melted down in a reverberatory furnace in a more or less oxidizing atmosphere and then further subjected to an oxidizing

Electrolytic Refining Meaning,

2 Electrolytic refining is a process of refining a metal (mainly copper) by the process of electrolysis. As far as the mechanism of the process is concerned, during

Chapter 7 Energy Use in the Copper Industry Princeton

19961120 Energy Requirements in Proven and New Copper Processes,re- port prepared for the U.S. Department of Energy, contract no, EM-78-S-07-1 743, December

The use of solar energy in the copper mining processes: A

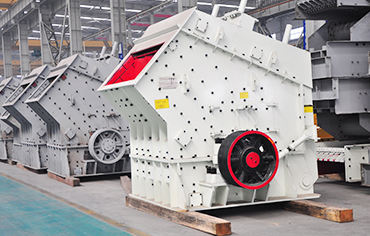

2021101 The most intensive energy-consuming process is the grinding process. Low-grade heat (Temperatures <80 °C) is necessary for efficient copper refining. Besides, considerable water is consumed in the flotation and leaching stages. Fuels are required to power transportation and excavation activities.

(PDF) Energy EfficiencyCopper

200811 The results demonstrate that hydrometallurgical processes consume significantly less energy than the alternative grinding, flotation, smelting

Processing of Complex Materials in

202076 Copper smelter and refinery with a copper cathode production capacity of 70,000 tpa. A precious metal plant is also integrated into the base metal operation to

Innovations: How Hydrometallurgy

202253 The SX/EW Process. The SX/EW Process is a hydrometallurgical process since it operates at ambient temperatures and the copper is in either an aqueous

Copper Refining an overview ScienceDirect Topics

Application Areas Miscellaneous Process Industries. David Reay, Adam Harvey, in Process Intensification (Second Edition), 2013. 10.5.1.5 Copper extraction using emulsion liquid membranes. Solvent extraction has been routinely used for copper refining since its invention in the 1960s, and it is suggested that well over 10% of refined copper

17.5: Refining of Copper Chemistry

2022720 1. Figure 17.5. 1: The electrolytic purification of copper. In such a cell a thin sheet of high-purity Cu serves as the cathode, and the anode is the impure

Integration assessment of the hybrid sulphur cycle with a

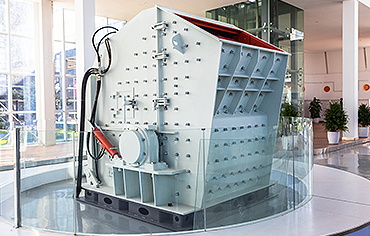

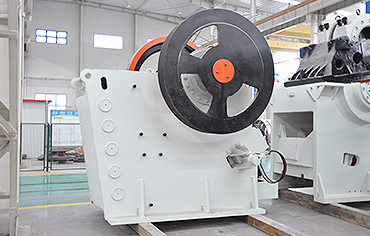

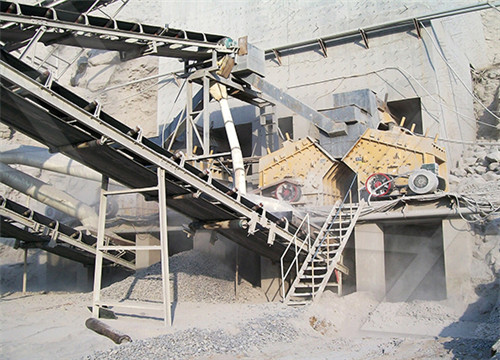

2021121 In the copper refining process (Fig. 1 (a)), the mined rock is first ground in a crushing unit and then separated, typically via a floatation unit, into sulphide-containing (chalcocite (Cu 2 S), covellite (CuS) and chalcopyrite (CuFeS 2)), and oxide-containing (tenorite (CuO) and cuprite (Cu 2 O)) products.The sulphide ore is processed via a

COPPER Copper production TU Delft

20081216 1. Beneficiation by froth flotation of ore to give copper concentrate (Optional partial roasting to obtain oxidized material or calcines) 2. Two-stage pyrometallurgical extraction 1. smelting concentrates to matte 2. converting matte by oxidation to crude (converter or blister) copper 3. Refining the crude copper, usually in

Chapter 7 Energy Use in the Copper Industry Princeton

19961120 Energy Requirements in Proven and New Copper Processes,re- port prepared for the U.S. Department of Energy, contract no, EM-78-S-07-1 743, December 1980. The hypothetical open-pit mine described in table 7-2 uses an average of 20 million Btu of energy per ton of cathode copper produced, or about 21 percent of the energy

Electrolytic Refining Meaning,

2 Electrolytic refining is a process of refining a metal (mainly copper) by the process of electrolysis. As far as the mechanism of the process is concerned, during

The use of solar energy in the copper mining processes: A

2021101 The most intensive energy-consuming process is the grinding process. Low-grade heat (Temperatures <80 °C) is necessary for efficient copper refining. Besides, considerable water is consumed in the flotation and leaching stages. Fuels are required to power transportation and excavation activities.

(PDF) Energy EfficiencyCopper

200811 The results demonstrate that hydrometallurgical processes consume significantly less energy than the alternative grinding, flotation, smelting

Processing of Complex Materials in

202076 Copper smelter and refinery with a copper cathode production capacity of 70,000 tpa. A precious metal plant is also integrated into the base metal operation to

Innovations: How Hydrometallurgy

202253 The SX/EW Process. The SX/EW Process is a hydrometallurgical process since it operates at ambient temperatures and the copper is in either an aqueous

Copper Refining an overview ScienceDirect Topics

Application Areas Miscellaneous Process Industries. David Reay, Adam Harvey, in Process Intensification (Second Edition), 2013. 10.5.1.5 Copper extraction using emulsion liquid membranes. Solvent extraction has been routinely used for copper refining since its invention in the 1960s, and it is suggested that well over 10% of refined copper

17.5: Refining of Copper Chemistry

2022720 1. Figure 17.5. 1: The electrolytic purification of copper. In such a cell a thin sheet of high-purity Cu serves as the cathode, and the anode is the impure

Integration assessment of the hybrid sulphur cycle with a

2021121 In the copper refining process (Fig. 1 (a)), the mined rock is first ground in a crushing unit and then separated, typically via a floatation unit, into sulphide-containing (chalcocite (Cu 2 S), covellite (CuS) and chalcopyrite (CuFeS 2)), and oxide-containing (tenorite (CuO) and cuprite (Cu 2 O)) products.The sulphide ore is processed via a

Copper Refining: Explained Step-by-Step

2017210 In refining copper, the metal is melted down in a reverberatory furnace in a more or less oxidizing atmosphere and then further subjected to an oxidizing

COPPER Copper production TU Delft

20081216 1. Beneficiation by froth flotation of ore to give copper concentrate (Optional partial roasting to obtain oxidized material or calcines) 2. Two-stage pyrometallurgical extraction 1. smelting concentrates to matte 2. converting matte by oxidation to crude (converter or blister) copper 3. Refining the crude copper, usually in

Development of a Flowsheet for Recovering Copper and

20151227 1990). Pyro-hydrometallurgical methods are also used for the treatment of copper converter flue dusts and copper refining slags (taken from Sarkuysan A.S., Turkey) (Geveci et al., 2000; Yıldız et al., 2000). Alkali roast-acid leach process is reported in the literature for recovering metals from converter slag (Das et al., 1999).