أرسل لنا رسالة

jaw crusher description in nigeria franklin miller crushers

What Is a Jaw Crusher? Here's How It Works Cutting

2021218 Whether it’s creating aggregates or mining, jaw crushers are your go-to. Jaw crushers were created in 1858 by Eli Whitney Blake. And since then, they’ve only

Jaw Crusher an overview ScienceDirect Topics

For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape. Assuming in this case the largest particle to be crushed is 85% of the gape,

Crushers All crusher types for your

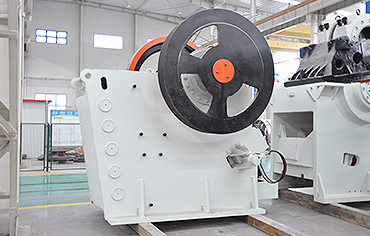

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes,

Jaw Crushers McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first

What is a Jaw Crusher? MEKA Crushing Equipment

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within

What Are Jaw Crushers and How Do

2019328 March 28, 2019 / in News. A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks. The equipment was first

Jaw Crusher Explained saVRee

How Jaw Crushers Are Sized. Jaw crushers are sized based upon the dimensions of the top feed inlet (gape) or the dimensions of the jaws. For example, a 32 x 54 sized jaw crusher

Jaw Crushers thomasnet

Specifications of jaw crushers include 25 in. L x 19 in. W x 30 in. H28 in. L x 19 in. W x 32 in. H dimensions, 2 hp to 3 hp power, 400 rpm speed, onethree phase operation, 1/16

Jaw Crushers high quality and reliability from RETSCH

The crushing ratio of a jaw crusher results from the maximum achievable final fineness in relation to the maximum feed size. For Retsch jaw crushers, this lies between 12.5 and 220. A high value reflects the capacity of a jaw crusher to accept large sample pieces and provide powerful crushing performance, resulting in high final fineness.

What Is a Jaw Crusher? Here's How It Works Cutting

2021218 Whether it’s creating aggregates or mining, jaw crushers are your go-to. Jaw crushers were created in 1858 by Eli Whitney Blake. And since then, they’ve only become more widespread. This article will focus on what jaw crushers are and how they’re used in the professional setting. What is a Jaw Crusher? A jaw crusher may sound like

Fine Jaw Crushers

The fine jaw crusher range includes: Essa® JC1250 Fine Jaw Crusher the scaled down and more affordable version of our fine jaw crushers. Evolved from an intensive two-and-a-half-year research and development program to

® C Series™ jaw crushers Metso Outotec

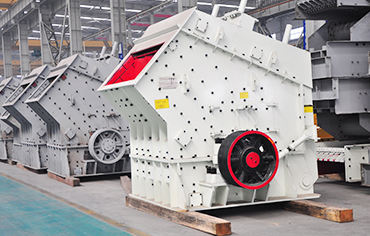

The core of ® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers. In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that

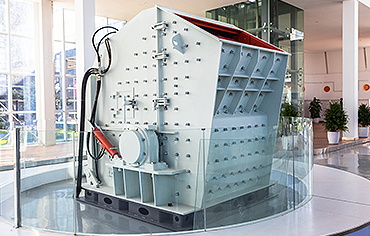

Types of Crushers: What You Need to Know Machinery

The demand for large-mouthed jaw crushers skyrocketed as the industry began to understand their potential as primary crushers in rock quarries. Through Thomas A. Edison’s research and development, giant machines were innovated and placed around the United States. Smaller-sized jaw crushers were also developed as secondary and tertiary crushers.

Industrial Solutions Jaw crushers ThyssenKrupp

20221121 Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

Nigerian Journal of Technology Vol. 36, No. 3, July 2017 815 this is being done with a view to revealing ways to improve its performance. 1.1 Overview of Crushing Process in A Single Toggle Jaw Crusher The feed supplied to a single toggle jaw crusher through its gape, is crushed by the compression of the feed by the

Jaw Crusher Eastman Rock Crusher

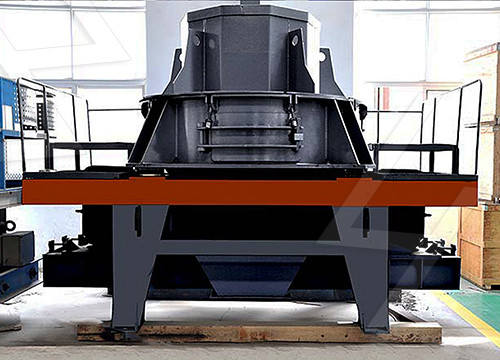

Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications mining, quarry, construction waste recycling, aggregate making, etc. Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone,

Crushers, Pulverizers, Grinders Lavallab

For over 35 years Laval Lab Inc is the one-stop specialist for size reduction of all types of materials. We have the right crusher, pulveriser, grinder or mill for the laboratory to

Liner wear in jaw crushers Request PDF ResearchGate

2003131 Abstract. Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these costs. Being able to predict the

Jaw Crushers high quality and reliability from RETSCH

The crushing ratio of a jaw crusher results from the maximum achievable final fineness in relation to the maximum feed size. For Retsch jaw crushers, this lies between 12.5 and 220. A high value reflects the capacity of a jaw crusher to accept large sample pieces and provide powerful crushing performance, resulting in high final fineness.

® C Series™ jaw crushers Metso Outotec

The core of ® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers. In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that

Fine Jaw Crushers

The fine jaw crusher range includes: Essa® JC1250 Fine Jaw Crusher the scaled down and more affordable version of our fine jaw crushers. Evolved from an intensive two-and-a-half-year research and development program to

Industrial Solutions Jaw crushers ThyssenKrupp

20221121 Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately

Jaw Crusher Eastman Rock Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications mining, quarry, construction waste recycling, aggregate making, etc. Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone,

Crushers, Pulverizers, Grinders Lavallab

For over 35 years Laval Lab Inc is the one-stop specialist for size reduction of all types of materials. We have the right crusher, pulveriser, grinder or mill for the laboratory to

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

Nigerian Journal of Technology Vol. 36, No. 3, July 2017 815 this is being done with a view to revealing ways to improve its performance. 1.1 Overview of Crushing Process in A Single Toggle Jaw Crusher The feed supplied to a single toggle jaw crusher through its gape, is crushed by the compression of the feed by the

Liner wear in jaw crushers Request PDF ResearchGate

2003131 Abstract. Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these costs. Being able to predict the

GATOR series Jaw-Crusher|Best Jaw-Crusher|GATOR U.S.

2019425 Jaw Crusher. Product overview. As a leading Jaw Crusher manufacturer in China, GATOR is committed to various jaw crushers and screening equipment design, manufacturing and sales, The jaw crushers can crush various material with compressive resistance less than 320Mpa, Feed size is from 125mm to 750mm, and with features of

Design, Fabrication and Testing of a Double Roll Crusher

20221021 Roll Crusher # Egbe, E.A.P. 1*, and Olugboji, O.A.1 1 Department of Mechanical Engineering, School of Engineering and Engineering Technology, Federal University of Technology, Minna, Nigeria Abstract-A developing nation like Nigeria, with huge deposit of different solid minerals and rocks, needs to explore the processing of