أرسل لنا رسالة

Crusher start-up curve

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT

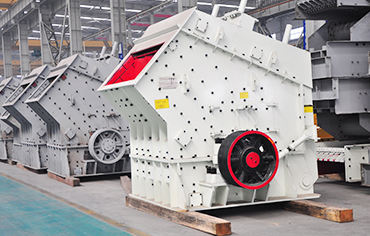

product curve. Example: CV216 crusher fitted with a 50Hz 110Kw motor. Tip Speed 52 M/Sec. Rotor throughput 120 tph Bi-Flow® material = 23 tph. i.e. Rotor throughput x 20%. Total crusher throughput 143 tph. Varying the ratios of rotor to Bi-Flow® feed material

: 874KB(PDF) A performance model for impact

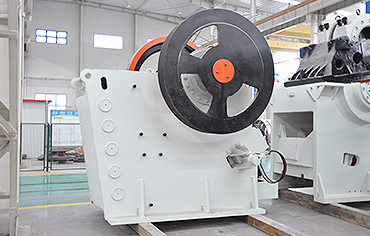

2002101 Jaw crushers reduce rock sizes between a fixed and moving jaw while cone crusher crush the rock

: Svetoslav NikolovSize reduction control in cone crushers ScienceDirect

2021111 To evaluate the effect of liner wear on cone crusher size reduction, a similar test sequence is first performed for a crusher with fully worn liners and then for

: Pekka Itävuo, Matti VilkkoCrushing Plant Startup Sequence

2016126 Start either cone crusher lube pumps and allow 5 seconds for pressure to build up and oil to be

:6Crushers Mining ABB

With the precise speed and torque provided by our low and medium voltage AC drives, the mechanical stress on the crusher and the motor is vastly reduced from smooth

[PDF]Industrial Solutions Jaw crushers ThyssenKrupp

20221121 the curves will shift to the right. (Throughput by way of example based on a bulk density of 1.6 t/m 3) The throughput rates of the standard ver sion of the single

Simulation and optimization of gyratory crusher

2020101 To study and optimize the gyratory crusher performance, taking the process of crushing iron ore by the gyratory crusher as the specific analysis object in this

fr/crusher start curve.md at main hedaokuan/fr

Contribute to hedaokuan/fr development by creating an account on GitHub.

Crushing Products Size and Shape

2016226 The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the

Compressor Start‐Up Procedures Wiley Online Library

2019415 Abstract This chapter contains sections titled: Compressor Start-Up Risks Generic Start-Up Procedure Centrifugal Compressor Start-Ups Reciprocating

(PDF) A performance model for impact

2002101 Jaw crushers reduce rock sizes between a fixed and moving jaw while cone crusher crush the rock between an external fixed element (bowl liner) and an

Crushers Mining ABB

With the precise speed and torque provided by our low and medium voltage AC drives, the mechanical stress on the crusher and the motor is vastly reduced from smooth

Size reduction control in cone crushers ScienceDirect

2021111 To evaluate the effect of liner wear on cone crusher size reduction, a similar test sequence is first performed for a crusher with fully worn liners and then for the same crusher with new liners. Based on the acquired data, relative production curves and performance maps J 1 J 4 are finally established using ordinary least squares.

[PDF]Industrial Solutions Jaw crushers ThyssenKrupp

20221121 the curves will shift to the right. (Throughput by way of example based on a bulk density of 1.6 t/m 3) The throughput rates of the standard ver sion of the single-toggle jaw crusher are based on easily crushable, medium-hard feed material. The throughput rates of the hard-rock version of the single-toggle jaw crusher are based on

Simulation and optimization of gyratory crusher

2020101 To study and optimize the gyratory crusher performance, taking the process of crushing iron ore by the gyratory crusher as the specific analysis object in this . First, the discrete element method (DEM) analysis model of the iron ore based on the bonded-particle model (BPM) is established. On this basis, the impacts of the mantle

Determination of start-up curves for a boiler with natural

2015121 The start-up pressure and temperature curves were determined for the critical thick-walled components like the drum and outlet header of the final superheater. The computations were carried out using the European Standard EN 12952-3 and a method developed by the co-authors of the .

Gyratory Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. 5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1].The smaller form is described as a cone crusher. The larger crushers are normally known as primary

Crushing Products Size and Shape

2016226 The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the

[PDF]Modelling of crushing operations in the aggregates

201532 Matlab. Using the curve fitting software package GnuPlot, functions were ascertained that fit the data from JKSimMet. It was found that these functions were based on the Rosin-Rammler distribution for large enough values of CSS. The effect of changing the feed size distribution was investigated for the gyratory crusher. The feed

Compressor Start‐Up Procedures Wiley Online Library

2019415 Abstract This chapter contains sections titled: Compressor Start-Up Risks Generic Start-Up Procedure Centrifugal Compressor Start-Ups Reciprocating Compressor Start-Ups Screw Compressor Start-Ups

Crushing Plant Startup Sequence

2016126 Start either cone crusher lube pumps and allow 5 seconds for pressure to build up and oil to be circulated through the crusher. Start conveyor #3 (30

Size reduction control in cone crushers ScienceDirect

2021111 To evaluate the effect of liner wear on cone crusher size reduction, a similar test sequence is first performed for a crusher with fully worn liners and then for the same crusher with new liners. Based on the acquired data, relative production curves and performance maps J 1 J 4 are finally established using ordinary least squares.

Determination of start-up curves for a boiler with natural

2015121 The start-up pressure and temperature curves were determined for the critical thick-walled components like the drum and outlet header of the final superheater. The computations were carried out using the European Standard EN 12952-3 and a method developed by the co-authors of the .

Simulation and optimization of gyratory crusher

2020101 To study and optimize the gyratory crusher performance, taking the process of crushing iron ore by the gyratory crusher as the specific analysis object in this . First, the discrete element method (DEM) analysis model of the iron ore based on the bonded-particle model (BPM) is established. On this basis, the impacts of the mantle

[PDF]Modelling of crushing operations in the aggregates

201532 Matlab. Using the curve fitting software package GnuPlot, functions were ascertained that fit the data from JKSimMet. It was found that these functions were based on the Rosin-Rammler distribution for large enough values of CSS. The effect of changing the feed size distribution was investigated for the gyratory crusher. The feed

Compressor Start‐Up Procedures Wiley Online Library

2019415 Abstract This chapter contains sections titled: Compressor Start-Up Risks Generic Start-Up Procedure Centrifugal Compressor Start-Ups Reciprocating Compressor Start-Ups Screw Compressor Start-Ups

Gyratory Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. 5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1].The smaller form is described as a cone crusher. The larger crushers are normally known as primary

Crushing Products Size and Shape

2016226 The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the

AMIT 145: Lesson 2 Classifying Cyclones

Example: Partition Curve Development. The mass yield of solids to the underflow has been determined to be 63% using the two-product formula. A particle size analyses of

Cone Crusher Configuration How Setup Your Crusher For

20201118 In this stone we will start up with a little bit of theory on what happens with the rocks as they pass through the crushing chamber. Crusher operated on 16 mm, 18 mm, and 20 mm (from left to right curve). In addition to finer gradation the capacity will also decrease. If you remember that the size of the choke zone determines the capacity