أرسل لنا رسالة

Weight of Hammer Crusher

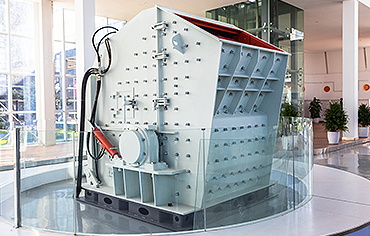

HAMMER CRUSHER HDS

Hammer Crushers used for primary crushing of soft to medium-hard rock with large feed size and high throughput rates HAMMER CRUSHER HDS. TECHNICAL

Hammer Crushers

’s double-shaft hammer crushers, with efficient 3-stage crushing operations, are mainly used in the cement industry for the comminution of soft to medium-hard material.

Hammer Crusher Machine Hammer Crusher Cement

202321 Hammer crusher machine. Production Capacity: 5-600m³/h. Feeding Size: ≤314mm. Application: coal, salt, gypsum, alums, brick, tile, limestone and etc. Get

Hammer Crusher: The 10 Most Important Points

2022815 Hammer crusher is a kind of crusher, mainly in the form of hammering, divided into two types: single rotor and double rotor. It plays a vital role in cement,

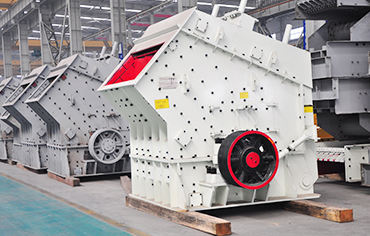

Hammer Crusher Machine Big Crushing Ratio And High

Our hammer crusher machine can save the energy more than 50% than the same type of products. This can reduce your running cost. The use of wear-resistant material can

double-shaft hammer crushers ThyssenKrupp

20221121 In double-shaft hammer crushers, the crushing of the feed material is mainly performed by the rotating hammers between the rotors and on the anvil. From

Environmentallly Friendly Hammer

1 The hammer crusher is used to crush a variety of medium hard and abrasive material whose compressive strength below 100 MPa and water content ess than 15%.

HAMMER CRUSHER Crushing/Grinding

2021114 Easy Maintenance. Multi-sectional welded housing allows easy access to every partition and quick exchange of wear parts. Hammners are always operated with

Hammer Crusher Working for Cement

The structure design of a hammer crusher. We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and

Hammer Crushers

’s double-shaft hammer crushers, with efficient 3-stage crushing operations, are mainly used in the cement industry for the comminution of soft to medium-hard material. When you need an Industrial Solution...

Hammer Crusher For Sale Large Crushing Ratio, Good

The heavy hammer crusher has a large weight of individual hammerhead, reasonable rotor speed, and large rotational inertia of hammerhead, which can achieve the crushing effect of large feed size and small discharge size. The heavy hammer crusher for stone can be equipped with a low voltage motor, high voltage motor, and double motors.

Hammer crusher All industrial manufacturers

Hammer Crusher advantages * Coarse and fine broken into one * Simplify the process * Compare this product Remove from comparison tool. 700 weight(t) Compare this product Remove from comparison tool. hammer crusher MC-1600HS. mobile crawler. hammer crusher. MC-1600HS. Capacity: 200 t/h 400 t/h Motor power: 105 kW Opening

Hammer Crusher Machine Big Crushing Ratio And High

Our hammer crusher machine can save the energy more than 50% than the same type of products. This can reduce your running cost. The use of wear-resistant material can reduce the wear of the lining plate and increase the service time. The body of hammer for crusheradopts sealing structure, which well solves the problem of dust pollution and dust

double-shaft hammer crushers ThyssenKrupp

20221121 In double-shaft hammer crushers, the crushing of the feed material is mainly performed by the rotating hammers between the rotors and on the anvil. From top: Hammer axle extraction device for TITAN ® crusher, type 96D180 TITAN® crusher, type 80D160, with hammer axle extraction device Grate basket trolley

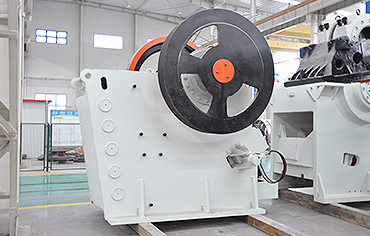

Hammer Crusher: The 10 Most Important Points

2022815 Hammer crusher is a kind of crusher, mainly in the form of hammering, divided into two types: single rotor and double rotor. It plays a vital role in cement, chemical industry, electric power, metallurgy, mining, and crushing industries. It mainly crushes medium-hard materials, such as limestone, slag, coke, coal mine, and dolomite.

Hammer Crusher Working for Cement

The structure design of a hammer crusher. We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and

EV hammer impact crusher

2020629 hammer impact crusher is a cost-effective solution for processing abrasive and moderately sticky raw materials in one stage. Horizontal feed system In a traditional hammer mill with a top inlet, large blocks in the feed may impede the action of the hammers and block the crusher. In the EV crusher, however, the horizontal feed system

(PDF) Redesign and Manufacture an Impact Crusher

2019213 The final results indicated that the new hammer produced a highest percentage of fine crushed particles compare with original one. The wear rates were 0.037 g/h and 0.023 g/h for the original and

THE EFFECT OF ROTOR BALANCE DURING CRUSHING

2020925 load with the weight necessary so that the crusher rotor becomes an unbalanced part in the opposite direction, we determine the weight of the compensation weight necessary to eliminate this Figure 2 Static balancing scheme for the crusher rotor Static balancing, despite its ease of implementation, is not suitable for a hammer mill rotor.

Hammer Crushers

’s double-shaft hammer crushers, with efficient 3-stage crushing operations, are mainly used in the cement industry for the comminution of soft to medium-hard material. When you need an Industrial Solution...

Large Capacity Hammer Crusher DASWELL

20221111 The hammer crusher is characterized by high capacity, high efficiency and low cost, and is mainly used for medium and fine crushing. It is simple in structure, small in size, light in weight and easy to transport. Customers can adjust the gap between the impact liner plate and plate hammer to produce different size of finished products.

Hammer Crusher For Sale Large Crushing Ratio, Good

The heavy hammer crusher has a large weight of individual hammerhead, reasonable rotor speed, and large rotational inertia of hammerhead, which can achieve the crushing effect of large feed size and small discharge size. The heavy hammer crusher for stone can be equipped with a low voltage motor, high voltage motor, and double motors.

Hammer crusher All industrial manufacturers

Hammer Crusher advantages * Coarse and fine broken into one * Simplify the process * Compare this product Remove from comparison tool. 700 weight(t) Compare this product Remove from comparison tool. hammer crusher MC-1600HS. mobile crawler. hammer crusher. MC-1600HS. Capacity: 200 t/h 400 t/h Motor power: 105 kW Opening

Hammer Crusher: The 10 Most Important Points

2022815 Hammer crusher is a kind of crusher, mainly in the form of hammering, divided into two types: single rotor and double rotor. It plays a vital role in cement, chemical industry, electric power, metallurgy, mining, and crushing industries. It mainly crushes medium-hard materials, such as limestone, slag, coke, coal mine, and dolomite.

double-shaft hammer crushers ThyssenKrupp

20221121 In double-shaft hammer crushers, the crushing of the feed material is mainly performed by the rotating hammers between the rotors and on the anvil. From top: Hammer axle extraction device for TITAN ® crusher, type 96D180 TITAN® crusher, type 80D160, with hammer axle extraction device Grate basket trolley

Hammer Crusher Machine Big Crushing Ratio And High

Our hammer crusher machine can save the energy more than 50% than the same type of products. This can reduce your running cost. The use of wear-resistant material can reduce the wear of the lining plate and increase the service time. The body of hammer for crusheradopts sealing structure, which well solves the problem of dust pollution and dust

Hammer Crusher Working for Cement

The structure design of a hammer crusher. We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and

EV hammer impact crusher

2020629 hammer impact crusher is a cost-effective solution for processing abrasive and moderately sticky raw materials in one stage. Horizontal feed system In a traditional hammer mill with a top inlet, large blocks in the feed may impede the action of the hammers and block the crusher. In the EV crusher, however, the horizontal feed system

THE EFFECT OF ROTOR BALANCE DURING CRUSHING

2020925 load with the weight necessary so that the crusher rotor becomes an unbalanced part in the opposite direction, we determine the weight of the compensation weight necessary to eliminate this Figure 2 Static balancing scheme for the crusher rotor Static balancing, despite its ease of implementation, is not suitable for a hammer mill rotor.