أرسل لنا رسالة

crusher principle diagram

Industrial Solutions Jaw crushers ThyssenKrupp

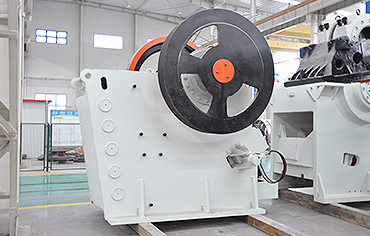

20221121 Schematic diagram of the working principle of a single-toggle jaw crusher with a single-toggle system Left: Single-toggle jaw crusher with main components

: 678KBCrusher an overview ScienceDirect Topics

Fig. 5.3 is a schematic diagram of a cone crusher. The breaking head gyrates inside an inverted truncated cone. Working principle of gyratory crusher for breaking lumpy ore

Working Principle of Crushers

2016217 The crusher head is at the moment in the close-side position. Crusher Working Principle. As the

:6Gyratory Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. 5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and

(a) Structure diagram and (b) functional principle diagram

The main objective is to investigate the impact of various crushing parameters like feed rate to jaw crusher and eccentric speed of Jaw crusher, closed side setting and throw in cone

(PDF) SIZE REDUCTION BY CRUSHING

201734 A simplified model (kinematic diagram) of the mechanism of the double buckling jaw crusher is shown in Fig. 20. The mechanism in question is a six membered

Cone Crusher Working Principle

2012815 Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from crushing chamber.

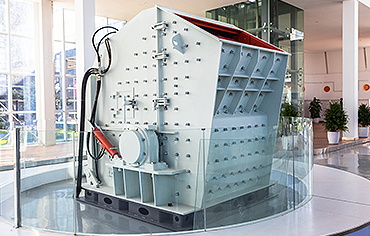

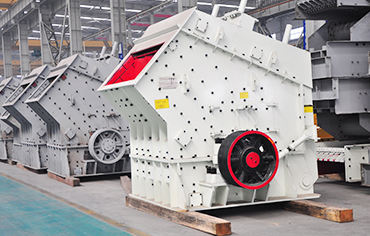

Working principle of impact crusher

2020514 (see Figure Impact Crusher 1 ) crusher working principle diagram for a typical counter. Broken material crusher, material is suspended by the plate

Roll Crushers ScienceDirect

201611 Roll crushers are arbitrarily divided into light and heavy duty crushers. The diameters of the light duty crushers vary between 228 and 760 mm with face lengths

[PDF]Industrial Solutions Jaw crushers ThyssenKrupp

20221121 Schematic diagram of the working principle of a single-toggle jaw crusher with a single-toggle system Left: Single-toggle jaw crusher with main components Crusher materials and jaw settings are shown in the diagram. The grain size distribution curves of the product are only guide lines. Deviations in the percentage composition are

[PDF]TECHNICAL NOTES 5 CRUSHERS Mineral Tech

2009730 Figure 5.1 Schematic diagram of a crusher showingg the open- and closed-side settings. 5.1 Jaw and Gyratory Crushers. Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is

(a) Structure diagram and (b) functional principle diagram

The main objective is to investigate the impact of various crushing parameters like feed rate to jaw crusher and eccentric speed of Jaw crusher, closed side setting and throw in cone crusher.

Types of Crushers: What You Need to Know Machinery

Parts diagram of a gyratory crusher Secondary Crushing Equipment. After materials receive their first round of crushing, they are fed into a secondary crusher to be reduced further. Average material sizes range from 350mm to 100mm during this output stage. Secondary crushing is especially important in the quarrying industry.

Roll Crusher an overview ScienceDirect Topics

The capacity of the single-roll crushers is a function of the roll gap, the roll length, and the speed, and ranges from about 30 tons/h (27 metric tons/h) for a 24-inch-long (61 cm) roll crushing to ¾ inch (2 cm), up to approximately 1500 tons/h (1360 metric tons/h) for an 84-inch-long (213 cm) roll crushing to pass 10 inches (25 cm).

Working principle of impact crusher

2020514 (see Figure Impact Crusher 1 ) crusher working principle diagram for a typical counter. Broken material crusher, material is suspended by the plate

(PDF) SIZE REDUCTION BY CRUSHING

201734 A simplified model (kinematic diagram) of the mechanism of the double buckling jaw crusher is shown in Fig. 20. The mechanism in question is a six membered

[PDF]DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

2016423 2. WORKING PRINCIPLE The crusher is designed to operate on a crank and slotted lever mechanism and the power for the electrical operation of the crusher is taken from an electrical motor. It is designed to use a 3 phase induction motor for the electrical operation of the crusher as the power required

[PDF]Industrial Solutions Gyratory crushers ThyssenKrupp

20221121 crusher configuration. The feed material should be at least 20% smaller than the width of the feed open ing. Arrangement drawing with fitting dimensions and loads on request. Large feed opening 3,080 x 1,675 mm Jaw gyratory crusher for underground iron ore mining and the crushing chamber of a BK 63-75 in a stationary copper ore plant

Block diagram of automatic can crusher machin

Download scientific diagram Block diagram of automatic can crusher machin from publication: Development of an automatic can crusher using programmable logic controller The invention of a can

[PDF]TECHNICAL NOTES 5 CRUSHERS Mineral Tech

2009730 Figure 5.1 Schematic diagram of a crusher showingg the open- and closed-side settings. 5.1 Jaw and Gyratory Crushers. Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is

(a) Structure diagram and (b) functional principle diagram

The main objective is to investigate the impact of various crushing parameters like feed rate to jaw crusher and eccentric speed of Jaw crusher, closed side setting and throw in cone crusher.

Types of Crushers: What You Need to Know Machinery

Parts diagram of a gyratory crusher Secondary Crushing Equipment. After materials receive their first round of crushing, they are fed into a secondary crusher to be reduced further. Average material sizes range from 350mm to 100mm during this output stage. Secondary crushing is especially important in the quarrying industry.

Working principle of impact crusher

2020514 (see Figure Impact Crusher 1 ) crusher working principle diagram for a typical counter. Broken material crusher, material is suspended by the plate

Roll Crusher an overview ScienceDirect Topics

The capacity of the single-roll crushers is a function of the roll gap, the roll length, and the speed, and ranges from about 30 tons/h (27 metric tons/h) for a 24-inch-long (61 cm) roll crushing to ¾ inch (2 cm), up to approximately 1500 tons/h (1360 metric tons/h) for an 84-inch-long (213 cm) roll crushing to pass 10 inches (25 cm).

[PDF]DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

2016423 2. WORKING PRINCIPLE The crusher is designed to operate on a crank and slotted lever mechanism and the power for the electrical operation of the crusher is taken from an electrical motor. It is designed to use a 3 phase induction motor for the electrical operation of the crusher as the power required

Gyratory Crushers Mineral

2016217 Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It

[PDF]Industrial Solutions Gyratory crushers ThyssenKrupp

20221121 crusher configuration. The feed material should be at least 20% smaller than the width of the feed open ing. Arrangement drawing with fitting dimensions and loads on request. Large feed opening 3,080 x 1,675 mm Jaw gyratory crusher for underground iron ore mining and the crushing chamber of a BK 63-75 in a stationary copper ore plant

Gyratory Crusher l Introduce, Working

1. Double-chamber gyratory crusher is a crusher machine that continues working with a double-chamber. The crusher equipment changes the discontinuous working mode of

Block diagram of automatic can crusher machin

Download scientific diagram Block diagram of automatic can crusher machin from publication: Development of an automatic can crusher using programmable logic controller The invention of a can