أرسل لنا رسالة

mobile crusher ore mining by mechanical means

Mobile Crushers Mineral Processing

20151223 Semi mobile crushers are still operated at the mining face but are not moved as often as the mobile

Types of Crushing Equipment Jaw,

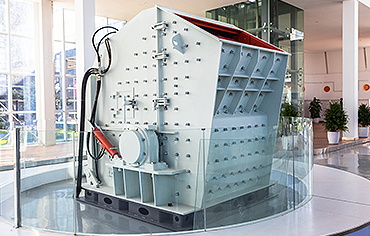

Choosing The Right Crusher A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific

Gyratory Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. 5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and

Crushing in Mineral Processing

20151226 After the mine has blasted the ore, the first reason why we crush rock is really to be able to transport

Crusher an overview ScienceDirect Topics

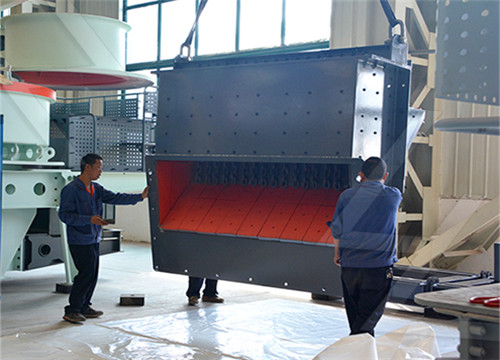

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing

HSE Quarries Safe operation and use of mobile jaw

20221123 Fig. 2 Excavator feeding mobile stone crusher. Blocked crushers Causes . Causes of crusher blockages can be grouped under two main headings: Stalling due to:

Mobile Crushers Graduate from

20101120 Ordered as a replacement for an existing crusher, the new unit is capable of handling minus-1,200 mm run-of-mine ore at a throughput rate of 3,500 t/h. The new

Ore Pass Mining Fundamentals AZoMining

2014524 An ore pass is a vertical or near-vertical opening, which is created during underground mining operations to transfer materials. It is designed based on the

Going underground: To scalp or not to scalp? Metso

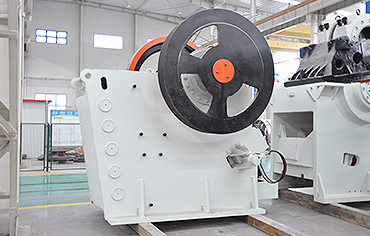

2014922 Scalping is recommended for a jaw crusher for three main reasons: Capacity increases when material below the crusher setting bypasses the crusher; also

(PDF) Rock Fragmentation by Blasting

201691 Abstract and Figures. Rock Fragmentation by Blasting a review The rock fragmentation process in mining currently being practiced in India needs re

(PDF) SIZE REDUCTION BY CRUSHING

201734 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and

Crushers QueensMineDesignWiki

2019628 Figure 1 : Crusher Location in an Underground Mine (ugdsb.on.ca) Material Handling. The material handling portion of crushing is the means by

Mobile Crushers Mineral Processing

20151223 Semi mobile crushers are still operated at the mining face but are not moved as often as the mobile crusher.. A movable crusher is positioned in the mine’s

HSE Quarries Safe operation and use of mobile jaw

20221123 Fig. 2 Excavator feeding mobile stone crusher. Blocked crushers Causes . Causes of crusher blockages can be grouped under two main headings: Stalling due to: Electrical or mechanical failure ; Material jammed in the chamber causing an overload ; Overfeeding material ; Entry of tramp metal or ; Accumulation of material in the

Crushing in Mineral Processing

20151226 After the mine has blasted the ore, the first reason why we crush rock is really to be able to transport it onto the next same. A Crusher’ Settings 3 main

(PDF) SIZE REDUCTION BY GRINDING

201734 The process Comminution involves size reduction and size-wise classification called as screening/ separation. Milling is one of the most important industrial

Crushers Mining ABB

With the precise speed and torque provided by our low and medium voltage AC drives, the mechanical stress on the crusher and the motor is vastly reduced from smooth

Evaluation and Risk Analysis of Open

2019410 Mining of raw materials is a process that consists of several stages. In open-pit mining, material with high compressive strength is extracted by drilling and

(PDF) Rock Fragmentation by Blasting

201691 Abstract and Figures. Rock Fragmentation by Blasting a review The rock fragmentation process in mining currently being practiced in India needs re

Mining and processing plant engineering design

2022814 ESFC, an international company, offers financing and engineering design for mining and processing plants under an EPC contract, including research, development of individual technical solutions, etc.

In-pit crushing and conveying systems

2017216 The purpose of an IPCC system is to allow the ore to be crushed in the pit and transported out using a conveyor system. In-pit crushers can be mobile which

(PDF) SIZE REDUCTION BY CRUSHING

201734 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and

Crushers QueensMineDesignWiki

2019628 Figure 1 : Crusher Location in an Underground Mine (ugdsb.on.ca) Material Handling. The material handling portion of crushing is the means by

Crusher an overview ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The

Mobile Crushing MetallurgistMineral Processing

20151223 part in mining operations is to fit the mine plan to the restrictions of the mobile conveying system. The conveying system is less flexible but also has to serve the whole mine. According to drilling and blasting you need to con-sider the maximum rock size that the mobile crusher will be fed with. Furthermore, you need to

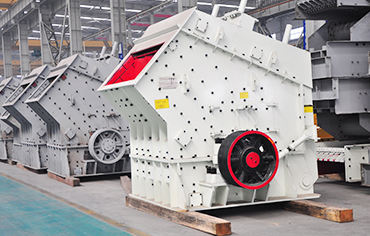

(PDF) Design of Impact stone crusher

2019531 rock chunks from a mining face became much larger, and "Thesis on horizontal shaft impact crusher," Mechanical Engineering, India, 2007. The

(PDF) SIZE REDUCTION BY GRINDING

201734 The process Comminution involves size reduction and size-wise classification called as screening/ separation. Milling is one of the most important industrial

Crushers Mining ABB

With the precise speed and torque provided by our low and medium voltage AC drives, the mechanical stress on the crusher and the motor is vastly reduced from smooth