أرسل لنا رسالة

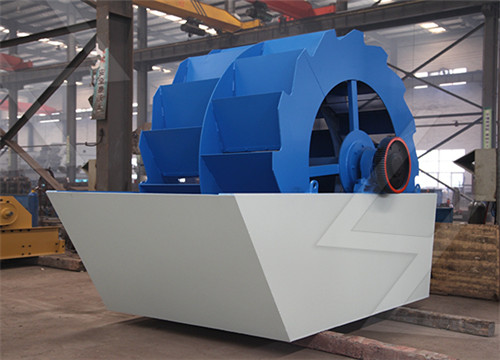

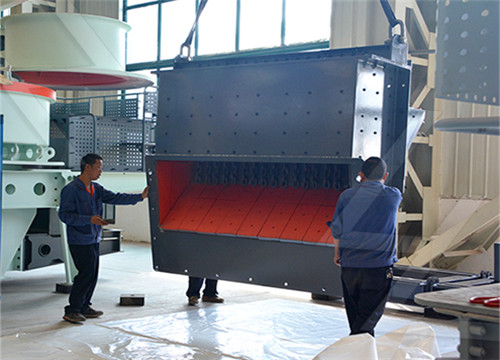

iron mill scale washing plant

Minerals Free Full-Text Recovery of Iron from Mill Scale

2021517 The mill scale is a waste from the iron and steel industry. Due to the high content of iron in the form of oxides, it is an attractive material for the recovery of metallic iron by reduction. The product of mill scale reduction is an iron with a very extended

(PDF) Analysis of methods for processing oily mill scale

202191 The stone considers the main methods of processing oily mill scale and oily sludge for iron and steel production. Available plants make it possible to process 7.3

Utilising of the oiled rolling mills scale in iron ore sintering

201121 Scale contains 69–72% of iron in the form of oxides and is relatively clean in sulphur, phosphorus and alkalis ( Noskov, 2002 ). Depending on the steel grade, it also

(PDF) STUDY OF IRON EXTRACTION FROM MILL SCALE

202061 Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, consisting of the mixed iron oxides iron (II) oxide (FeO), iron (III) oxide (Fe 2 O 3),

An overview of utilization of slag and sludge from steel

200731 The process byproduct of mill scale from the rolling process containing >70% Fe is generally recycled into the sintering plant. Generally, 70–100% mill scale

sbm/sbm iron mill scale washing plant.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Economical and Environmental

2019613 Mill scale is the by-product of iron and steel industry. It can be recycled via sinter plant or solid as sinter feed materials. 85 to 90% of the constituent particles are

CHAPTER 5. STUDY OF IRON EXTRACTION FROM MILL

Mill scale is formed on the outer surfaces of plates, sheets or profiles when they are being produced by rolling red hot iron or steel billets in rolling mills.[1] Mill scale is bluish-black

Utilising of the oiled rolling mills scale in iron ore sintering

201121 An industrial trial was carried out to capture mill scale particles from the fast-moving flume wastewater with a strong magnet at an ArcelorMittal hot rolling plant. The

Washing and Classifying Equipment For Sale IronPlanet

From Classification Tank and Material Washer to Wash Plant, you can buy and sell Washing and Classifying Equipment at IronPlanet from any and all manufacturers, including AMP,

Overview on production of reduced iron powder from mill

202111 Mill Scale, generated in a rolling steel mill can be a potential material for iron powder production. Mill scale is a combination of different oxides like Hematite (Fe 2 O 3), Magnetite (Fe 3 O 4), and Wustite (FeO),.Besides, this multi-oxide mill scale's conversion into single oxide (Fe 2 O 3) is the best-suited route for further reduction into iron powder

(PDF) Analysis of methods for processing oily mill scale

202191 The stone considers the main methods of processing oily mill scale and oily sludge for iron and steel production. Available plants make it possible to process 7.3 million tons of slags per

(PDF) STUDY OF IRON EXTRACTION FROM MILL SCALE

202061 Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, consisting of the mixed iron oxides iron (II) oxide (FeO), iron (III) oxide (Fe 2 O 3), and iron (II,III) oxide

An overview of utilization of slag and sludge from steel

200731 The process byproduct of mill scale from the rolling process containing >70% Fe is generally recycled into the sintering plant. Generally, 70–100% mill scale containing high iron is being recycled through either briquetting or sintering route with out any difficulties. In some cases, de-oiling of the material is required.

Assessment of recycling potential of the oily mill scale in

201811 The metallic iron, from the mill scale composition, can be reused as a source of raw material in the steelmaking process (from which it originates) or in other metallurgical processes. M. Houbart, PLD Erection of a demonstrative de-oiling plant for recycling oily steelmaking sludge and mill scales, LIFE11 ENV/LU/000855. Google

An Overview: Utilization of Iron Ore Fines and Steel Plant

201985 The current stone presents some preliminary results of a laboratory scale investigation which involves pelletization of mill scale, using steel plant waste as an additive and subsequent reduction

Utilising of the oiled rolling mills scale in iron ore sintering

201121 An industrial trial was carried out to capture mill scale particles from the fast-moving flume wastewater with a strong magnet at an ArcelorMittal hot rolling plant. The results show that the dynamically-separated flume mill scale is much cleaner, containing about 6–30 time less oil than the conventional statically-separated pit mill scale.

An Assessment of the Metallic Iron Content from Steel Mill

202222 The ten steel mill scale samples were collected from the technological flow of the steel rolling and the ten steel mill scale samples were collected from the Crişeni landfill. The determination of the total and metallic iron in the steel mill scale samples was achieved by using a spectrometer based on X-ray fluorescence.

Economical and Environmental Friendly Methods for

2019622 Mill scale is a precious waste material because it contains 65‐70% iron [1]. Mill scale is a very attractive industrial waste due to its richness in iron. In various iron and steel making processes, near about 500 kg/ton of solid wastes of various natures are produced and generated [2]. Mill scale is during the metallurgical process in the steel

12.5 Iron And Steel Production US EPA

2015910 12.5.1.2 Iron Production Iron is produced in blast furnaces by the reduction of iron bearing materials with a hot gas. The large, refractory lined furnace is charged through its top with iron as ore, pellets, and/or sinter; flux as limestone, dolomite, and sinter; and coke for fuel. Iron oxides, coke and fluxes react with the

Overview on production of reduced iron powder from mill

202111 Mill Scale, generated in a rolling steel mill can be a potential material for iron powder production. Mill scale is a combination of different oxides like Hematite (Fe 2 O 3), Magnetite (Fe 3 O 4), and Wustite (FeO),.Besides, this multi-oxide mill scale's conversion into single oxide (Fe 2 O 3) is the best-suited route for further reduction into iron powder

Utilising of the oiled rolling mills scale in iron ore sintering

201121 Scale contains 69–72% of iron in the form of oxides and is relatively clean in sulphur, phosphorus and alkalis ( Noskov, 2002 ). Depending on the steel grade, it also may contain alloying metals (Cr, Ni, V etc.). Formed by oxidation on the surface of metal at rolling operation, scale is removed by the water jet.

(PDF) Analysis of methods for processing oily mill scale

202191 The stone considers the main methods of processing oily mill scale and oily sludge for iron and steel production. Available plants make it possible to process 7.3 million tons of slags per

An overview of utilization of slag and sludge from steel

200731 The process byproduct of mill scale from the rolling process containing >70% Fe is generally recycled into the sintering plant. Generally, 70–100% mill scale containing high iron is being recycled through either briquetting or sintering route with out any difficulties. In some cases, de-oiling of the material is required.

Assessment of recycling potential of the oily mill scale in

201811 The metallic iron, from the mill scale composition, can be reused as a source of raw material in the steelmaking process (from which it originates) or in other metallurgical processes. M. Houbart, PLD Erection of a demonstrative de-oiling plant for recycling oily steelmaking sludge and mill scales, LIFE11 ENV/LU/000855. Google

An Overview: Utilization of Iron Ore Fines and Steel Plant

201985 The current stone presents some preliminary results of a laboratory scale investigation which involves pelletization of mill scale, using steel plant waste as an additive and subsequent reduction

An Assessment of the Metallic Iron Content from Steel Mill

202222 The ten steel mill scale samples were collected from the technological flow of the steel rolling and the ten steel mill scale samples were collected from the Crişeni landfill. The determination of the total and metallic iron in the steel mill scale samples was achieved by using a spectrometer based on X-ray fluorescence.

Utilising of the oiled rolling mills scale in iron ore sintering

201121 An industrial trial was carried out to capture mill scale particles from the fast-moving flume wastewater with a strong magnet at an ArcelorMittal hot rolling plant. The results show that the dynamically-separated flume mill scale is much cleaner, containing about 6–30 time less oil than the conventional statically-separated pit mill scale.

Economical and Environmental Friendly Methods for

2019622 Mill scale is a precious waste material because it contains 65‐70% iron [1]. Mill scale is a very attractive industrial waste due to its richness in iron. In various iron and steel making processes, near about 500 kg/ton of solid wastes of various natures are produced and generated [2]. Mill scale is during the metallurgical process in the steel

12.5 Iron And Steel Production US EPA

2015910 12.5.1.2 Iron Production Iron is produced in blast furnaces by the reduction of iron bearing materials with a hot gas. The large, refractory lined furnace is charged through its top with iron as ore, pellets, and/or sinter; flux as limestone, dolomite, and sinter; and coke for fuel. Iron oxides, coke and fluxes react with the