أرسل لنا رسالة

hammer mill speed torque characteristics

Full article: Optimizing hammer mill performance through

201449 The chip size can range from approximately 2 inches (5 cm) down to less than 0.25 inches (0.6 cm) in size. Once the first-stage grinding or chipping is completed, the feedstock is milled to the desired particle size. Hammer mills are common equipment for

sbm hammer mill speed torque characteristics.md main

Sign in / Register Toggle navigation Menu. S sbm ; Project information Project information Activity

(PDF) Design and Evaluation of

201911 A grain size reduction hammer mill for crushing corn (Zea mays L.) was designed depending on

A comparative study of new and traditional designs of a

2015622 The tested designs of the hammer mill differed mostly in the shape of the hammers. A characteristic shape indicator was the hammer angle (α). In the experiment,

Comminution features in an impact hammer mill

201321 The effect of the feed rate and the rotor speed on the mill efficiency in terms of reduction ratio, energy expenditure, fines produced and median size is investigated.

(PDF) DESIGN AND EVALUATE OF A

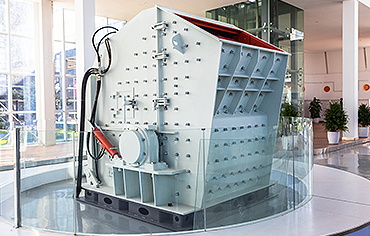

201596 Schematic of design hammer mill 1-Main frame ,2-Single phase Electrical motor 1 k Watt, 3-Hammer mill housing Image of the fabricated hammer mill Figures

Hammer mill

Hammer mill Device description Adopt modular integrated design, hammercrushing minimum particle size up to 30 μ m.Brushless DC motor drive and DC governor knob

en/typical speed torque charectristics of a ball mill.md at

Contribute to jidafang2022/en development by creating an account on GitHub.

Development and Performance

2018722 The least average particle sizes the modified hammer mill produced were 0.0098μmm, 0.0106 μmm, and 0.0088μmm compared to 0.019 μmm, 0.017

hammer mill speed torque characteristics

Hammer Mill Speed Torque Characteristics. 2021-7-27 July 27, 2021 Hammer Mill Operating Principle. Feb 25 2016 Operational Characteristics The method of operation has a con

Full article: Optimizing hammer mill performance through

201449 The chip size can range from approximately 2 inches (5 cm) down to less than 0.25 inches (0.6 cm) in size. Once the first-stage grinding or chipping is completed, the feedstock is milled to the desired particle size. Hammer mills are common equipment for this stage of mechanical preprocessing.

Optimizing hammer mill performance through screen

202232 Hammer mills have a wide application in biomass size reduction because of their simple design, ruggedness and versatil ity [16]. Fine or especially difficult to grind materials are often best comminuted using high-speed hammer mills with small diameter rotors [3]. High tip speeds result in material striking the outlet screen at steep angles,

(PDF) Investigating granular milling in a hammer mill

2011531 The milling equipment (Wiley Mill, Thomas Scientific, Swedesboro, NJ) used in our study is a variable speed, digitally controlled, direct drive mill; that provides continuous variation of cutting

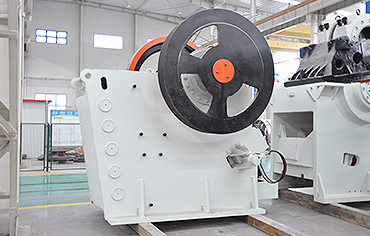

DESIGN, FABRICATION AND TESTING OF A

2014711 SIZE HAMMER MILL AJAKA E.O. and ADESINA A. that the main shaft speed of 913.5 rpm transmitted by a belt drive from a three horse power used in mineral processing industries because of its desirable characteristics which include . International Journal of Engineering and Advance Technology Studies Vol.2, No.2, pp. 11-21, June

Performance Analysis of a Modified Laboratory Hammer

20201015 Size reduction is the process of reducing large unit masses into small unit masses, coarse or fine particles (Sushat and Archna 2013).Hammer mill is a size reduction machine that consists of high speed swinging hammers mounted on rotor which impacts on the materials fed into it and get them disintegrated to finer particles such that it could

EXPERIMENT AND MODEL-BASED INVESTIGATION OF

2014121 A variable speed, digitally controlled, direct drive Wiley Mill, procured from Thomas Scientifi c (Swedesboro, NJ), was used in our experimental milling study. The mill provides continuous variation of rotational speeds (of hammers) from 600 to 1140 rpm with constant torque maintained throughout the speed range.

Direct mechanical energy measures of hammer mill

2009710 Large hammer mill bearings contributed to torque resistance.Effect of speed on total and effective specific energy. Average total specific energy, E t, of switchgrass, wheat straw, and corn stover increased by 37, 30, and 45%, respectively, with an increase in hammer mill speed from 2000 to 3600 rpm. Conclusions

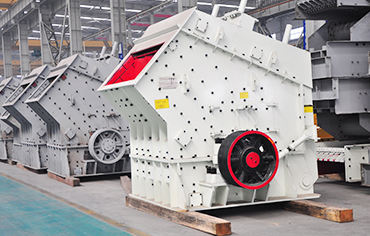

DEVELOPMENT AND TESTING OF A HAMMER MILL

2015922 The machine is of hammer mill type. In this case, there is hammer-like projection mounted on a shaft. The hammer revolves at high speed and grinds the materials fed into pieces by beating. Moreover, the machine can mill only the dry materials. The machine is incorporated with a detachable sieving mechanism to ensure fineness of

hammer mill constant torque or variable torque?

200971 The hammer mill drive motor is 4000V, 4000hp, 600rpm. I am considering changing the speed of the drive motor by rewinding and am trying to characterize the load. So Does a hammer mill respond like a variable torque load or a constant torque load? If we change the speed, does the power change proportionally or as a square or cube?

en/typical speed torque charectristics of a ball mill.md at

Contribute to jidafang2022/en development by creating an account on GitHub.

sbm hammer mill speed torque characteristics.md main

Sign in / Register Toggle navigation Menu. S sbm ; Project information Project information Activity

Optimizing hammer mill performance through screen

202232 Hammer mills have a wide application in biomass size reduction because of their simple design, ruggedness and versatil ity [16]. Fine or especially difficult to grind materials are often best comminuted using high-speed hammer mills with small diameter rotors [3]. High tip speeds result in material striking the outlet screen at steep angles,

Full article: Optimizing hammer mill performance through

201449 The chip size can range from approximately 2 inches (5 cm) down to less than 0.25 inches (0.6 cm) in size. Once the first-stage grinding or chipping is completed, the feedstock is milled to the desired particle size. Hammer mills are common equipment for this stage of mechanical preprocessing.

Performance Analysis of a Modified Laboratory Hammer

20201015 Size reduction is the process of reducing large unit masses into small unit masses, coarse or fine particles (Sushat and Archna 2013).Hammer mill is a size reduction machine that consists of high speed swinging hammers mounted on rotor which impacts on the materials fed into it and get them disintegrated to finer particles such that it could

EXPERIMENT AND MODEL-BASED INVESTIGATION OF

2014121 A variable speed, digitally controlled, direct drive Wiley Mill, procured from Thomas Scientifi c (Swedesboro, NJ), was used in our experimental milling study. The mill provides continuous variation of rotational speeds (of hammers) from 600 to 1140 rpm with constant torque maintained throughout the speed range.

Direct mechanical energy measures of hammer mill

2009710 Large hammer mill bearings contributed to torque resistance.Effect of speed on total and effective specific energy. Average total specific energy, E t, of switchgrass, wheat straw, and corn stover increased by 37, 30, and 45%, respectively, with an increase in hammer mill speed from 2000 to 3600 rpm. Conclusions

DEVELOPMENT AND TESTING OF A HAMMER MILL

2015922 The machine is of hammer mill type. In this case, there is hammer-like projection mounted on a shaft. The hammer revolves at high speed and grinds the materials fed into pieces by beating. Moreover, the machine can mill only the dry materials. The machine is incorporated with a detachable sieving mechanism to ensure fineness of

hammer mill constant torque or variable torque?

200971 The hammer mill drive motor is 4000V, 4000hp, 600rpm. I am considering changing the speed of the drive motor by rewinding and am trying to characterize the load. So Does a hammer mill respond like a variable torque load or a constant torque load? If we change the speed, does the power change proportionally or as a square or cube?